When it comes to guns, I’m not ashamed to say that I think of myself as a bit of an expert on most things…history, function, disassembly, etc. Oh, sure, you bring out something esoteric enough like a Gewehr41 or a Rast-Gasser and you’ll probably stump me on something like disassembly, but by and large I’d say I’m pretty darn good.

At least, that’s what I thought until working on the rather plebian Beretta 92. As a good survivalist, I figured I should have at least a couple 92’s laying around since the military uses/used them and therefore there’d be surplus (or ‘liberated’) parts and mags aplenty. But, I don’t like manual safeties on a double-action gun. There’s no need, since the gun is DA and usually carried with the hammer down.

Beretta eventually recognized this and has a variant, designated as ‘G’, where the safety acts as a decocker only. (Much like my dear Ruger P95DC pistols.) Beretta makes the conversion available as a kit for about $55. So..I ordered one. Step one was to disassemble the existing safety from the slide. I did so and as I looked at the back of the slide I saw this:

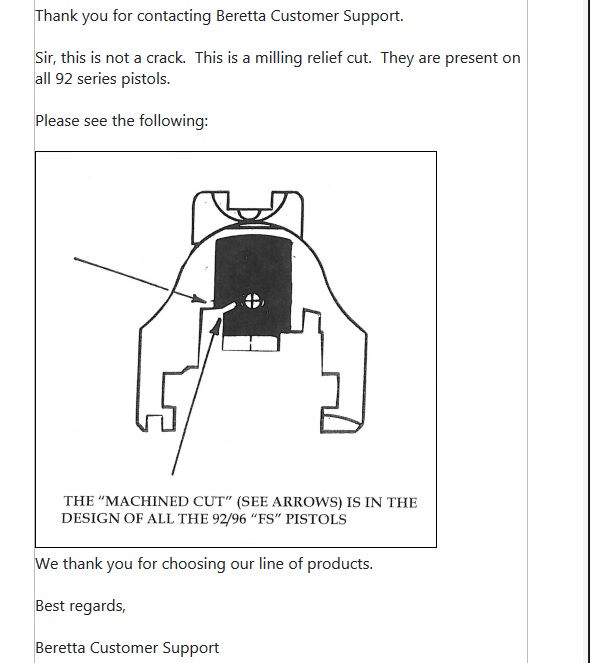

Well, bloody hell….the slide is cracked. And I kicked myself for not inspecting the gun more closely when I bought it years ago. Alright, let’s go to Beretta’s customer service and see if we can wheedle a new slide from them since this one clearly is broken. Their reply:

Well, bloody hell….the slide is cracked. And I kicked myself for not inspecting the gun more closely when I bought it years ago. Alright, let’s go to Beretta’s customer service and see if we can wheedle a new slide from them since this one clearly is broken. Their reply:

It’s supposed to look like that. I have to give kudos to Beretta CS for a) replying within 48 hrs and b) not calling me a dumbass.

It’s supposed to look like that. I have to give kudos to Beretta CS for a) replying within 48 hrs and b) not calling me a dumbass.

I’ve taken apart a lot of pistols in my years of gun fondling. You look at the back of a 1911, Glock, Sig, HiPower, Ruger, etc, etc, and that hole for the firing pin is always solid. I’ve never seen a relief cut in that area of a pistol. But..I’m not a machinist, not a mechanical engineer, and not a metals stress expert. So, if the guys at Beretta, who have been making boomtoys for several hundred years, say “No, no, dude….it’s supposed to look like that”, well, I guess that’ll have to do.

But….it sure looked like a stress fracture to me.

Clearly I need more time tinkering with Berettas. But it was a bit sobering to realize that, maybe I don’t know it all after all. Maybe I should have read the warning printed on the slide:

By the way, the G conversion was a breeze if you ignore Beretta’s incredibly complicated online instructions and just YouTube your way through it. (ProTip: watch video, watch video again.) Took me about ten minutes to get it installed and it works like a champ. A lot of folks carry guns like this with the hammer down and safety off, which is reasonably safe. However, those same people are usually concerned about the safety accidentally becoming engaged as the gun is bumped around or brushed up against things…last thing you want is to grab your gun, bring it up, pull the trigger and have nothing happen because the safety you left in the off position has somehow engaged itself. This G conversion prevents that.

By the way, the G conversion was a breeze if you ignore Beretta’s incredibly complicated online instructions and just YouTube your way through it. (ProTip: watch video, watch video again.) Took me about ten minutes to get it installed and it works like a champ. A lot of folks carry guns like this with the hammer down and safety off, which is reasonably safe. However, those same people are usually concerned about the safety accidentally becoming engaged as the gun is bumped around or brushed up against things…last thing you want is to grab your gun, bring it up, pull the trigger and have nothing happen because the safety you left in the off position has somehow engaged itself. This G conversion prevents that.

I work for the Navy and one of my command functions is to check ships equipment material condition. I accompanied our command small arms inspector on one of his visits to a destroyer. He checked out every firearm arm on board the ship over a period of a week. One of the checks he performed was to check the M9 for slide cracks. I don’t know how many he found but their were always issues with the M9’s. Any he demined defective were sent back to the depot.

Awesome printed warning CZ – you made my morning! 🙂

Thanks for this. Bought the G conversion, as well. Haven’t installed it yet, since the Kung Flu means I’ve had 3 kids who won’t give me a minute’s peace. Once I’ve sold them to a chinese salt mine, maybe I’ll find time to do this.

DOn’t even bother with the Beretta-supplied instructions. They’ll just intimidate you. Go with theYouTube video. You’ll definitely need a hammer and proper size punch for the roll pins, though.

Had one put on my Centurion (slightly shorter bbl, same grip) after my safety/decocker broke, and I’ve been happy with it. Changing the hammer spring to the D model (DAO) was also a help with the first shot. It lowered it 2-3 lbs, making it much easier to be accurate with that first DA shot.

And the Beretta is very accurate, mores than its owner, for sure. Fun to shoot, and everyone who tries it is pleased with its ease of use and accuracy.

I’m guesstimeasuring that metal at ~0.014″ thick. (Looking at an earlier slide, the “F” model, which is what the M9 started as.) You have the FS (safety) version, that has the slide retention modification. That was done to keep the rear section of a broken slide from impacting you in the face if it breaks. Seems the SEALs were using subgun rated ammo which caused a few slides to fail, back in the late 80’s. A team contractor’s fix was to make a batch of solid hood slides for them (~2 dozen?), but Beretta’s engineers came up with a cheaper fix for the military’s contract that didn’t keep them from breaking, but did keep it from injuring the shooter if it did fail. Only the SEALs had breakage, IIRC.

Those proto/pilot run solid hood slides were never issued to the Teams, and ended up with various people involved with the project. Very collectible. The designer made two attempts to market the design to the public, but both times fate stuck a monkey wrench into the works. The first batch had to be destroyed when he won a court case that involved the company name on the slide, and lost ownership of the name while being paid ~$3m for another product he designed using that name. Wasn’t feasible to remove the logo. His second, and last, attempt failed when a sub-contractor machineshop ruined most, if not all, of the slides made with his new company name/logo. He was so pissed off by the whole thing that he would never talk about the civilian versions up to his death, I’ve been told.

I can understand his feelings regarding the subject. When idiots have screwed around with some of my designs, it feels like they are harming kids or pets, or similar. You get very attached when you invest a lot of time and effort into a creative endevour.

Had a housemate that was the primary machinist for the second attempt. The owner of the shop was the rocket engineer that built Evel Knievel’s Snake River rocket, Robert Truax. You know that thought about “six degrees of separation”? The world seems to be a lot smaller than you would think.

Years back I decided that the Beretta is a flawed design that was well executed. Now however it’s a flawed design that’s poorly executed. It’s overly complex from a design standpoint and relatively fragile.

I can shoot it well, I earned my distinguished pistol badge with one in military competition but it’s probably the worst service pistol of the last 50 years. We learned early on to keep a spare handy because they break so often. When our state competitive program started to draw attention due to some success we convinced the state to buy 10 new ones for us thinking that would solve our problem with parts breaking, we broke 5 of them the first time we took them to the range. It was honestly a rare thing for us to go through a competition without breaking one or more and military matches aren’t high round count events.

My advice would be to find people who have seen too many John Woo films and sell yours to them. I would never want to rely on one for anything serious.

Great points.

Just FWIW, I’ve had my G-17 since about ‘92. I’ve shot IPSC, 3-Gun and a host of other matches.

I’m well passed 100,000 rounds with it. The only replacement work I’ve done is sights, and springs. (Oh, and back in the day, I bought and sold a 17-L just for that light “trigger”.)

I still trust it. With my life.

Now that is odd. Why would a purposeful “crack” be there? I was in the Army when the trials for a new pistol took place and I remember reading some of the reports and the Beretta was the only make that suffered a catastrophic failure with slide cracks. Even more odd, the Ruger P85 was the only one that did not have a single hiccup. Yet the Army chooses the worst of the lot. Go figure.

The pistol trials were a sham, as the decision to buy the Beretta was a given, made at the executive level. It was a quid pro situation, the price for placing some missiles in Italy. The nitty gritty of politics at a glance!

When has testing been anything but a sham?

I suspect that the metal is so thin from the spaces needed for the safety lever assembly, that a crack would be common. It doesn’t appear to be a critical location, just subject to some flex from hammer strikes, so the decision was made to pre-crack it for appearance sake, most likely.

Not the first gun to have this done. The Colt Delta Elite, the 10mm 1911 model had the same thing done just above the slot for the slide release, as the frame flexed enough to cause it to crack in a non-critical location. Normally it is better to clean up this sort of thing, as self-induced cracks can generate debris, and sometimes travel to areas that become critical. That’s beside the point that it looks bad to the user.

Beretta has been around since 1526.

Pretty sure I acknowledged that with “Several hundred years”

The G-conversion is sold out on the Beretta site, but Langdon Tactical has them. Which got me looking at their Trigger Job In A Box. Wondering if you have experience with that and if so, how difficult you found it.

Got mine from Midway. No experience with the trigger kit.

It’s still polishing a turd. It’ll still be a flawed design. It’ll just be a flawed design that eliminates one of its many failings.

CZ has helped me justify the purchases of Rugers, Sigs and Glocks.

Beretta: ‘we designed a crack into the place it’s going to crack’ ? WTF

Actualy, thats not abad fix. Colt had trouble with their 1911 frames in 10mm cracking so they just cut away the part that cracked. An easy fix.

Man. I still want a NIB Delta Elite.

Yeah, I like my G-40, but…..

Sigh.

I had the 96 DAO model in .40 caliber. I didn’t like it for edc. Too bulky and I didn’t like the trigger. I ended up trading it in on a Sig 365. I much happier. Good luck your Beretta.

I think pretty much any DAO pistol is kinda bleah.

Now that’s just funny!

I would have thought it was broken as well. I still need to pick up a nice M9 type Beretta for the same reasons you stated. So many guns, so little time…